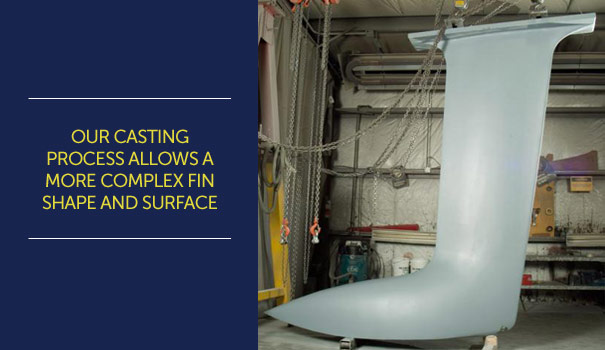

Cast Fins

MarsKeel has produced cast keel fins and bulbs for such boats as Maxis Racing Yachts down to 6.5m Mini. The material range for the production of the fins goes from Nickel Aluminum Bronze to Grey Iron, Ductile Iron to 316 Grade to 2205 Duplex Stainless Steel. This combination of processes allows the customer to get a more complex fin shape and surface than can be produced through fabrication.

Download : Cast Fins Info Sheet

Read : Cast Fins Info Sheet

GENERAL CASTING CONDITIONS

There are conditions of the casting process that are important to understand. Both the builder and the designer must recognize and accept the dimensional tolerances, or limitations to casting metal keel fins. The generally offered tolerance is +/- 0.125″ for bend, warp and twist. These possible movements occur during the cooling process of the metal, not unlike the shrinkage of lead as it cools. Some metals can be straightened or relaxed to remove the movement, whereas others, such as cast iron, cannot be straightened. This is simply a possibility and does not means that the movement will always happen during the fin casting it.

PRODUCTION PROCESS

Pattern Considerations

The production process of a cast metal fin begins with the production of the patterns. Each custom pattern is made from the customer’s drawings. The patterns have to incorporate the appropriate amount of shrinkage for the requested material as well as the required machine tolerance for any and all machined surfaces on the fin, on such areas as the mounting surface for the bulb and the hull. Other than any required surfacing, as mentioned, on the fin, any required fastener points, such as upper and lower keel bolt threaded holes, need to be machined in place.

Casting

Once the casting process is complete, the casting and material are checked for quality. These checks will include material properties, chemistry (through testing of a casting coupon) as well as straightness and inspection for any flaws. The general testing standard used is ASTM. Others certainly can be used but they need to be outlined, pass/fail criteria from the beginning of the project.

Once the fin is cast the customer (owner, designer or builder) will specify whether the fin is to be left in an as-cast state (other than the necessary machining) or if it is to be fully CNC machined. As mentioned above the full machining option does require the addition of machining tolerance to the fin, which is generally a minimum of 0.375”. This allows for the removal of any existing bend, warp or twist in the casting and the cutting of surface. Surfacing does require the casting of a slightly larger amount of material, reflected in the cost of the part.

Finishing Processes

From this point the fin can be sent to the finishing rooms for final fairing and painting. This process takes a very skilled touch and attention to detail. The actual process is slightly different for either the as-cast fin or the machined fin.

Fin Bulb Attachment

After the fin is complete there are also a couple of paths that it can take to match up with the required bulb. The bulb can be cast separately and mechanically attached to the fin or the bulb can be integrally cast onto the fin. The integrally casting process simplifies the casting of the bulb, no cores or holes are to be cast. It also removes the necessity for attachment to the fin. There are also some considerations made for the process during the design and pattern production. A below lead armature is required to hold the bulb. There is a limit to the physical size of the fin and bulb that can be integrally cast together. The limit is based on the ability to ship the finished part. Can the keel be placed on the truck bed or in the container?

Once the fin is faired it is sent to the shipping department for packaging and transportation to the customer.