Keel Bolt Replacement

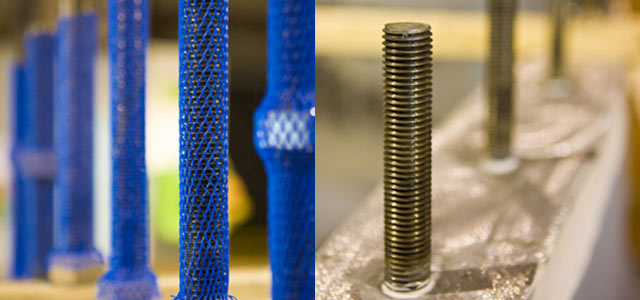

If your keel bolts have deteriorated to the point where they are unsafe, or have failed entirely, or have been damaged in an accident, they can be replaced. MarsKeel can offer you replacement technology and techniques that return your keel to new condition.

MarsKeel has the ability to replace damaged keel bolts in the original keel. Our technology allows us to remove damaged keel bolts from keels and install new bolts with no loss in the surface shape, strength or position relative to any untouched bolt.

The main benefit of this process over other methods is that it is stronger than simply threading in lag screws through the sump into the lead. With our system you do not run the risk of hitting the old bolt with the new fastener. Our method does, however require that the boat is hauled the keel be removed for the bolts to be replaced.

We can offer you any bolt material. However, generally speaking, most production boats would either have 304 or 316L grade Stainless Steel keel bolts.

Once the keel has had all the necessary bolts replaced it is brought to the packaging department where it is skidded for shipping. If it is possible, we will skid the keel upright to make installing it easier for the customer.

Whatever caused the bend in your keel, be it groundings or cradle collapses, our team of craftsmen can get you back in the water.

MarsKeel has the ability to straighten virtually any bent keel. As long as the lead is not fractured, we can repair the keel for a fraction of the cost of a new keel.

The damage can be a simple bend or a twist or a combination of both. Either way, we have the ability to bring the keel back into original shape. There are limits however to the amount of damage that the lead will allow you to remove. That limit is rarely, if ever reached in “normal” keel impacts. Where the limit is namely found is in the bending of the keel wings after grounding, when the boat is left to rock back and forth on the keel. If the wings are thin and long enough to bend into a “smile”, it is very unlikely that they will withstand the bending to return them to their original position.

We are not limited to just bent keels. We can also remove compound damage such as bends and twists. Our shop has the ability and equipment to hold and twist a keel back to within a fraction of an inch of its original shape.

We are not limited to just bent keels. We can also remove compound damage such as bends and twists. Our shop has the ability and equipment to hold and twist a keel back to within a fraction of an inch of its original shape.

Before the repair process is started the keel is inspected for all damage. A number of straight edges are set with multiple plumb bobs, and a laser is used to check and record the damage.

We will use the best sized press for the project. As mentioned in our Production Capacities, we have the ability to use up to a 1000 ton press in the straightening of the keel. This capacity allows us to apply sufficient force to straighten very large keels with very tight tolerances.

During the straightening process, the progress of the work is checked again by plumb bobs and lasers. This allows us and the customer to see where the keel started and where it is at any point during the work.

Once the keel is bent back into shape the entire keel is re-faired (by straight edges) using epoxy- or polyester-based fillers, and then coated with 6 coats of Interprotect 2000E and prepared to be reinstalled on the boat. The fairing process can be taken to either our Standard Production Finish or our High Grade Racing Finish.

Once the keel is straightened and faired it is sent to the packaging department where it is prepared for shipment back to the customer.